Progressive climate change led to the initiation of the Green Deal by the EU Commission in 2019. This set out the goal of achieving climate neutrality in the EU by 2050. Since 2019, various measures have been taken in connection with the Green Deal. These include, for example, the initiative to strengthen the circular economy in the automotive industry. In addition to the topics of sustainability and resilience, the Commission is also driving forward the topic of a more user-oriented industry.

Inspired by the Japanese concept of Society 5.0, which attempts to balance economic development with the resolution of social and environmental problems, the EU Commission developed the Industry 5.0 concept. It is nothing other than a fresh approach to industrial policy. Industry 5.0 is based on three key pillars: people, sustainability and resilience.

How Industry 5.0 puts values first

Progressive climate change led to the initiation of the Green Deal by the EU Commission in 2019. This set out the goal of achieving climate neutrality in the EU by 2050. Since 2019, various measures have been taken in connection with the Green Deal. These include, for example, the initiative to strengthen the circular economy in the automotive industry. In addition to the topics of sustainability and resilience, the Commission is also driving forward the topic of a more user-oriented industry.

Inspired by the Japanese concept of Society 5.0, which attempts to balance economic development with the resolution of social and environmental problems, the EU Commission developed the Industry 5.0 concept. It is nothing other than a fresh approach to industrial policy. Industry 5.0 is based on three key pillars: people, sustainability and resilience.

Industry 5.0: the value-driven evolution of Industry 4.0

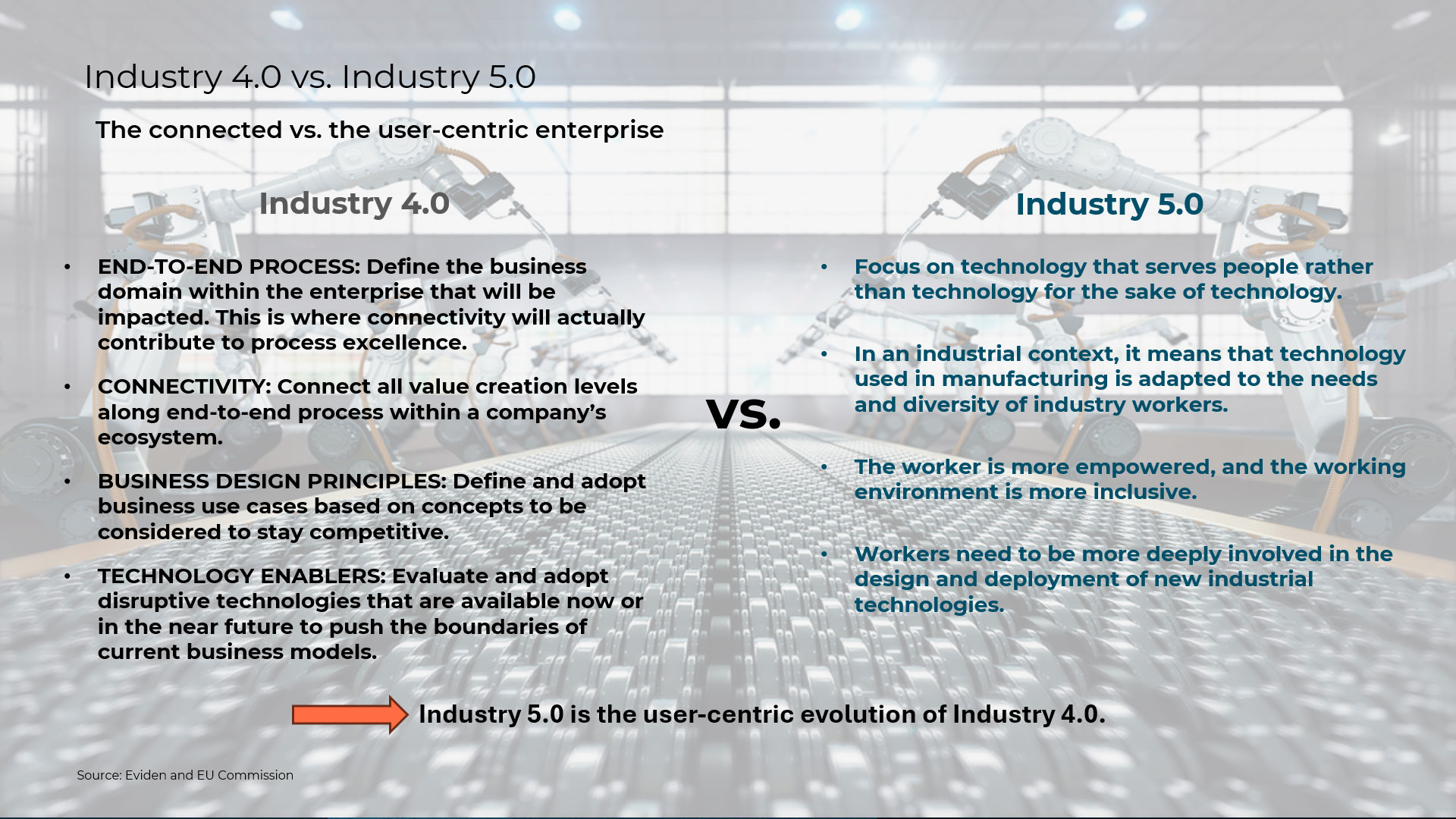

Industry 4.0 is largely technology-driven and propagates the improvement of the competitiveness of industrial companies through digital transformation toward networked value creation. On the other hand, Industry 5.0 pursues a value-driven approach (see Figure 1) that integrates Industry 4.0 technologies with the needs of employees.

The focus of Industry 5.0 is on the development of a circular economy with processes for the reuse, repurposing and recycling of products to strengthen sustainability. It also aims to increase the resilience of industrial processes to better deal with crises. The latter is particularly important considering the impact of Covid-19 and that of armed conflicts on European supply chains.

From a direct industry perspective, however, the key component is the focus on employees within the company. Under Industry 5.0, technology should be adapted to the needs of employees above all else, and employees should therefore be more closely integrated into the development and use of technology.

The advantages of Industry 5.0 are seen across its three pillars:

- People: achieving better motivation and work performance through greater employee integration

- Sustainability: future-proofing businesses by reducing the dependence of European industrial companies on raw material supplies from outside the EU

- Resilience: improving the ability to bounce back by implementing concepts such as modular production or real-time supply chain monitoring

Industry 5.0: changing processes in the industry

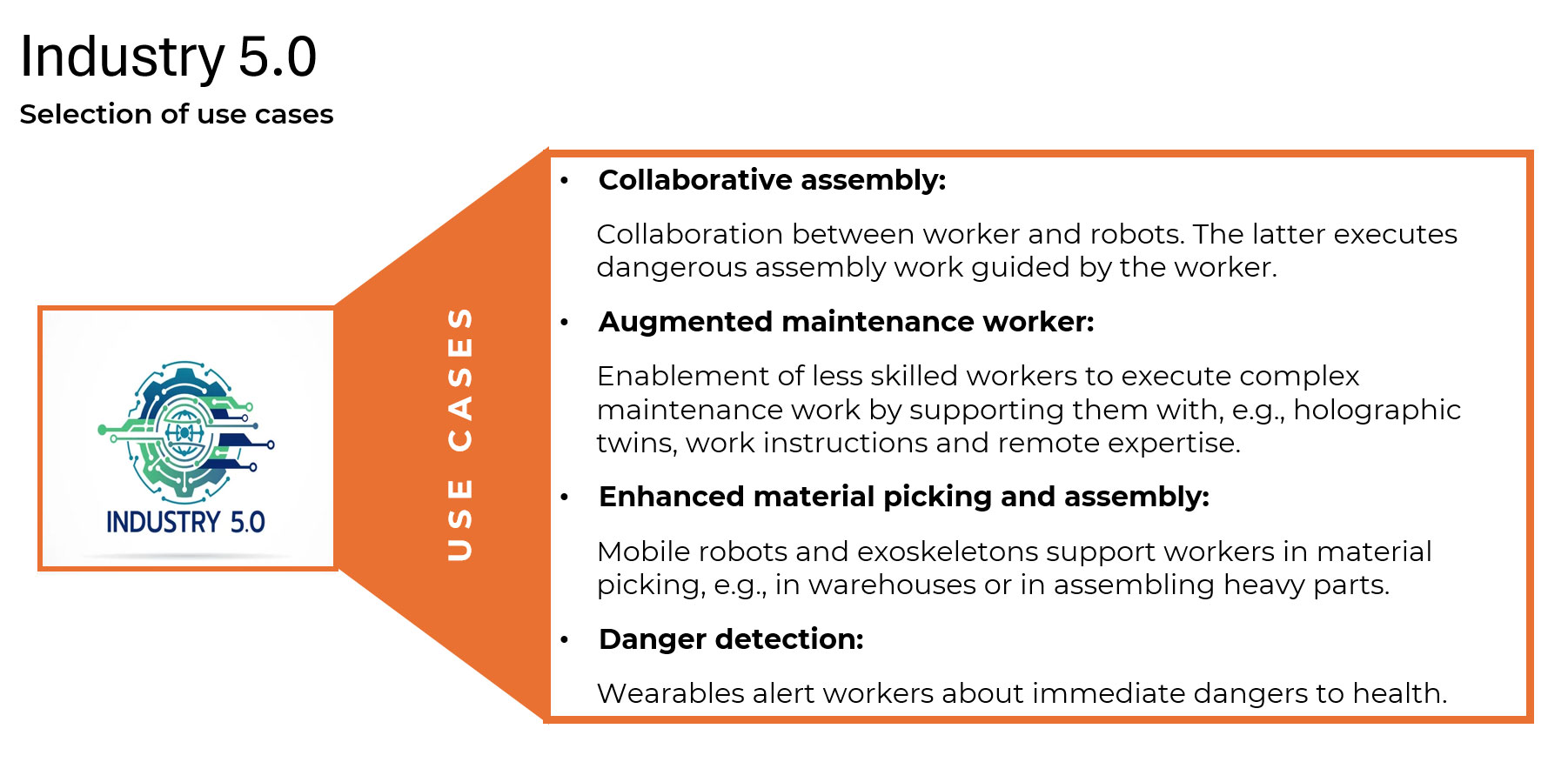

Regarding the people-oriented aspect, Industry 5.0 could change work processes in manufacturing, for example. Focusing on the needs of employees strengthens their role and improves the integration of their working environment. The use of technology improves the work situation, and not just optimizes processes and cost structures. Industry 5.0 will use the technologies developed under Industry 4.0 in this sense. Use cases in industrial production include:

- Take over of dangerous assembly tasks, e.g., in the production of turbine blades, by robots controlled by the employee

- Using augmented reality to allow highly qualified maintenance work to be carried out by less qualified persons This application is becoming increasingly important due to the growing shortage of skilled workers.

In addition, mobile (picking) robots and exoskeletons can help to improve the quality of work in the picking process at warehouses. Wearables can help employees to detect hazards, such as leaking liquids or gases, before they cause physical harm (see Figure 2).

Industry 5.0 and the future

Industry 5.0 is a concept of the EU Commission that could make a significant contribution to the realization of the Green Deal. The concept is currently under discussion. Like all top-down initiatives of the EU Commission, the prerequisite for the realization of Industry 5.0 is the approval of the member states. In addition, business associations will also try to influence this.

In contrast to Industry 4.0, which is a technology-driven initiative, Industry 5.0 also requires social and legal changes within the EU. One of the main prerequisites is the realization of a circular economy in the EU. As a result, the aspects of Industry 5.0 relating to sustainability and resilience will still have to overcome a number of bureaucratic hurdles. However, it will be possible to quickly implement a user-centric approach in companies using existing technologies such as augmented reality and AI.