In our years of working with manufacturers, Eviden’s SAP practice has witnessed how a seemingly simple challenge — order sequencing — can make or break a company’s operational success. I vividly remember a case of a COO who discovered his company had lost millions in a single quarter due to inefficient production scheduling. Traditional scheduling methods — a patchwork of spreadsheets and gut-feeling decisions — had transformed what should have been a precision instrument into a chaotic production nightmare.

The complexity of order sequencing

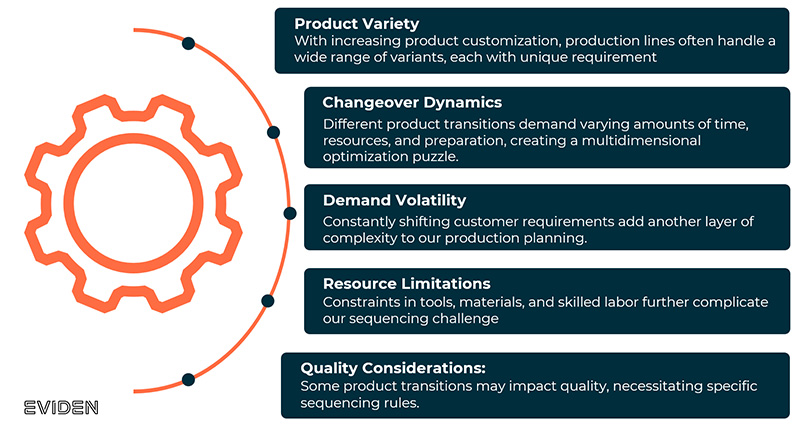

The complexity stems from several key factors described in Fig. 1.

Source: Eviden’s SAP practice

Why traditional methods fail

Conventional approaches to order sequencing are fundamentally inadequate in addressing these challenges:

- Rule-of-thumb methods oversimplify the complex interactions between production variables.

- Manual sequencing introduces human error and cannot simultaneously consider multiple constraints.

- Basic software solutions lack the sophistication to truly optimize our production sequences.

The technological solution: Advanced sequencing

Modern manufacturers are increasingly leveraging cutting-edge technologies at the heart of their operations to transform their business. This transformation relies on three interconnected technological capabilities that can turn order sequencing from a complex challenge into a strategic opportunity:

- AI and machine learning: Machine learning algorithms analyze historical production data to identify intricate patterns invisible to human schedulers. These systems learn from past production runs, continuously refining sequencing strategies. By recognizing subtle relationships between product transitions, machine learning can predict optimal sequences that minimize changeover times and maximize resource efficiency.

- Real-time data integration: Internet of Things (IoT) sensors have revolutionized production monitoring with instantaneous, granular insights into machine status, inventory levels and production progress. This real-time data stream enables manufacturers to make dynamic sequence adjustments, responding to changing conditions with unprecedented speed and precision.

- Advanced optimization algorithms: Sophisticated computational methods simultaneously evaluate multiple constraints and objectives. These algorithms quickly generate production sequences that balance competing priorities — minimizing changeover times, maximizing resource utilization, meeting delivery deadlines and maintaining product quality.

Unlike traditional approaches, advanced solutions based on these technologies offer a comprehensive, dynamic approach to production optimization.

Spotlight: Eviden’s Sequence Solver

Understanding these various pain points in shop floor scheduling, Eviden has developed Sequence Solver, a comprehensive solution.

Sequence Solver is a straightforward yet powerful SAP solution for schedulers. Leveraging Eviden’s intellectual property and powered by AI technology, it effectively sequences multiple orders from a diverse product portfolio on a single production line.

It’s built on SAP’s Business Technology Platform (BTP), so it takes material and order transaction data directly from SAP S/4HANA Cloud. The data is then processed using sophisticated AI algorithms and GenAI simulations to generate optimized order sequence scenarios. Through a user-friendly SAP Fiori interface, the planner can consider various scenarios and simulate or activate the right order sequence. The total cost of ownership (TCO) is low because it can be deployed in 2-4 weeks, and support is extremely simple.

The business impact of optimized sequencing

In our view, implementing advanced order sequencing triggers a strategic metamorphosis that could fundamentally reshape manufacturing capabilities.

Consider the multifaceted impact. Production costs are reduced, not just through minimized changeover times, but by holistically optimizing resource utilization. Inefficiencies are eliminated, and production capacity increases.

On-time delivery can be transformed from a challenging goal to a consistent reality. Manufacturers can now create more predictable and reliable production schedules, directly enhancing customer satisfaction and competitive positioning.

Perhaps most critically, advanced sequencing introduces unprecedented operational agility. Companies can now respond dynamically to market changes, fluctuating demand and unexpected challenges with a level of precision previously unimaginable.

Sequencing as a competitive advantage

Those who master this complex balance of technology and strategy will emerge as market leaders, turning operational complexity into a powerful competitive advantage.

Are you ready to master production efficiency? Order sequencing is the way to go.

Connect with me and let’s discuss how advanced order sequencing can transform your manufacturing performance.