Supply chain networks are the lifelines of businesses across the globe. However, these complex systems face unprecedented challenges — from pandemic-induced disruptions to wars to climate change. Then there are also everchanging consumer preferences.

As a business consultant immersed in the intricate tapestry of global supply chains, I see firsthand the pivotal role that stock safeguarding plays in our customers’ operations. But what exactly is stock safeguarding, and why does it matter now more than ever?

Imagine a scenario in which your most desirable items are cleared off the shelves in the twinkling of an eye, and consumers cannot buy them anymore. Production stopped due to a lack of parts. Or imagine a company buried in debt due to too much stock. This is not science fiction. It is reality for companies that don’t use stock-safeguarding strategies.

Importance of stock safeguarding

Stock safeguarding isn’t merely about ensuring that shelves remain stocked. It’s about safeguarding business resilience in the face of volatility.

It’s a buffer against unforeseen events, an insurance policy against supply chain hiccups and an assurance of meeting customer demands, come what may.

Challenges in stock safeguarding

Yet, for all its importance, stock safeguarding is no walk in the park. The challenges our customers encounter are as diverse and complex as the supply chains themselves.

- The ever-present spectre of demand unpredictability

Forecasting future demand is akin to reading tea leaves — it’s an imprecise science fraught with uncertainty. Consumer preferences can change on a whim. Market trends can shift overnight. And external factors beyond control can wreak havoc on projections. Consequently, accurately gauging how much stock to hold to meet anticipated demand without succumbing to excess or shortage is a perpetual balancing act.

- The labyrinthine nature of global supply chains

With operations spanning continents, navigating the web of suppliers, manufacturers, distributors, and logistics partners becomes an exercise in logistical gymnastics. Information asymmetry, communication barriers, and disparate systems only serve to muddy the waters, making it all the more difficult to maintain real-time visibility and coordination across the supply chain network.

- The allocation dilemma

In scenarios where demand outstrips supply, deciding which customers or orders to prioritize amid constrained resources is a high-stakes game. Balancing competing priorities such as order urgency, customer loyalty and profitability requires deft decision-making and strategic foresight. Manual allocation processes are labor-intensive, prone to errors, and ill-equipped to handle the pace and complexity of modern supply chains.

In actuality, many priorities vie for the same SKU-lot that must be allotted for concurrent customer orders. Systems must be able to comprehend this business nuance and offer a clear solution that adheres to the main business goal without sacrificing orders. Instead of subjectivity, where human bias is possible, modern technologies enable business users with a data-driven approach to tackling these difficult scenarios.

Leveraging technology: The role of SAP S/4HANA AATP

As an SAP partner for over 35 years, my team closely follows and evaluates the new solutions SAP releases constantly. Harnessing the power of advanced digital technologies and intelligent algorithms, SAP S/4HANA’s Advanced Available-To-Promise (AATP) solution promises to really offer a lifeline for businesses grappling with these stock safeguarding challenges.

We have seen that SAP’s AATP solution dynamically configures allocation rules, integrates with planning systems and makes real-time allocation decisions based on myriad criteria. It empowers businesses to navigate the choppy waters of global supply chains with confidence.

Approach for Advanced-Available-To-Promise (AATP) Handling ‘Allocations’

Stock Safeguarding Strategy

Flexibility to build business rules using S/4HANA AATP and SAP Integrated Business Planning (IBP)

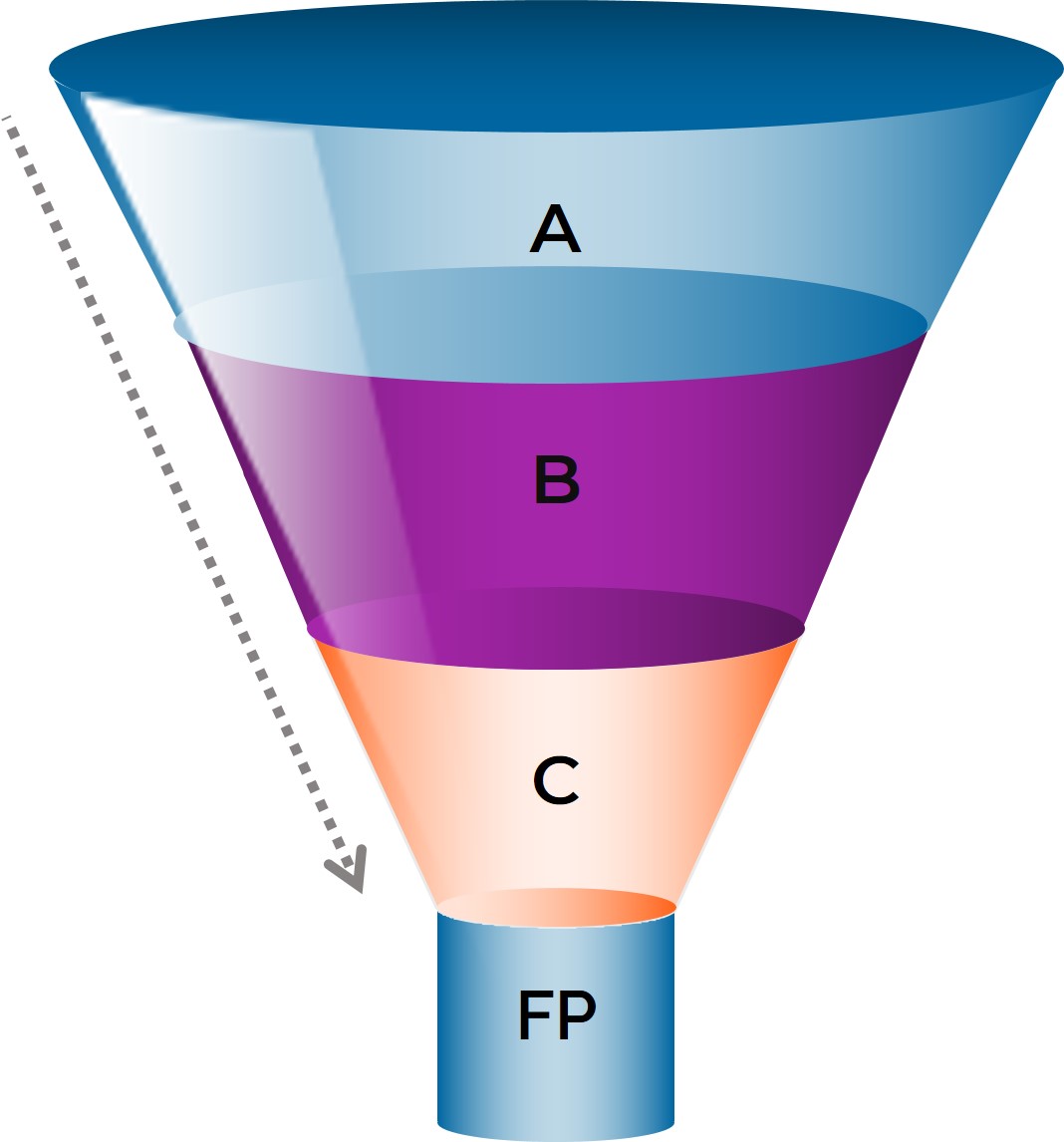

e.g., Customer segmentation A-B-C-FP (FP = free pool customers)

Dynamic allocation available sequential choice based on customer segmentation.

Remaining allocation: Free Pool (FP) – All customers thus prioritized fulfilled first. The dynamic demand situation still allows to cater all customers by predicting demand

SAP S/4HANA AATP has user-friendly apps to configure, execute and monitor the availability check process. It also has features to integrate any planning applications where product allocations typically are generated. The product allocation overview app, for instance, displays whether the relevant allocation is being executed as expected or not.

From what I’ve seen, SAP S/4HANA AATP product allocation effectively manages the order fulfillment process, enhancing order fulfillment KPIs within the supply chain. This enables multinational corporations to successfully fulfill customer orders.

Embracing solutions for a resilient future

Stock safeguarding isn’t just about keeping shelves stocked — it’s about safeguarding a business’ future. Solutions like SAP S/4HANA AATP help you fortify your supply chain against volatility, enhance customer satisfaction, and secure competitive edge in an ever-evolving marketplace. With SAP S/4HANA AATP by our side, we can help you navigate the turbulent seas of global supply chains with poise and purpose.

Let’s explore the challenges you face. See what we can learn from your stock safeguarding dilemmas and understand how SAP AATP could support you. Contact me today!