The COVID-19 pandemic has shown the limits of global supply chains, and how industrial production can be disrupted by a single global event. This has led companies to rethink the way they procure material and parts for their production in the future. The shortage of parts and materials delivered by international sources has put the spotlight on the concept of Manufacturing-as-a-Service (MaaS).

MaaS: The marketplace of the future

MaaS is a concept that offers companies to procure parts from third parties on demand i.e., when they need it. Organized as a marketplace with a software platform at its heart, MaaS supports the regionalization of supply chains, thereby promising faster and secure deliveries. The market for MaaS has shown a substantial growth since 2019. The four major players in the market have increased their business volume from €525 mil. in 2019 to €876 mil. in 2022, representing a CAGR of 19%.[1]

Let’s take a look at why this is finding favour among leading manufacturers across the globe.

Deconstructing the details of MaaS

Manufacturing as a service

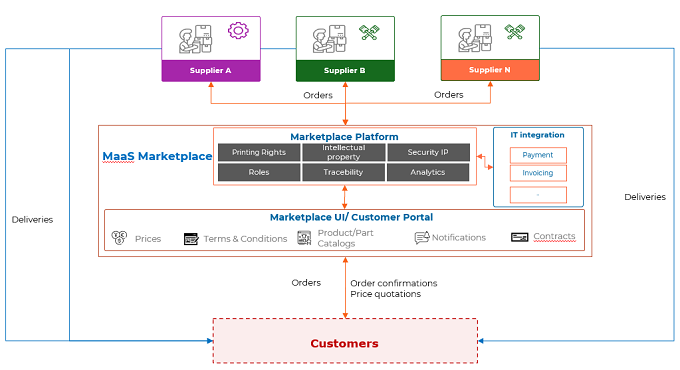

Marketplace Setup

Picture 1: A high-level design of a MaaS marketplace

In addition to offering features that enable customers to speed up their procurement process and reduce the time to delivery, the major criteria for the success of a MaaS platform is that quality and reliability is assured. This is why major MaaS providers in the market such as 3D Hub or Xometry have implemented strict procedures for onboarding new suppliers.

Typically, new suppliers undergo a detailed evaluation by executing several test orders before being onboarded to the marketplace. The quality of the manufacturers being part of the MaaS marketplace is prime. Furthermore, the marketplace needs to incorporate suppliers with a broad technology coverage like additive manufacturing and CNC machining, and critical size.

For the success of the MaaS marketplace, it is essential that the platform leverages advanced technologies such as AI, and provides interfaces to PLM and ERP systems. Economically, MaaS operators must cultivate a broad customer base, necessitating substantial efforts in marketing and sales. Overall, MaaS offers great benefits for customers and suppliers alike. Customers take advantage of a multitude of suppliers engaged in the marketplace and the transparency provided about pricing. MaaS platforms are a one stop shop easing the search for qualified suppliers.

Since these suppliers are mostly located in a region close to the customers, the latter will benefit from short delivery timelines. It is also a good instrument to add elasticity to their own manufacturing capacities in case they need additional capacities or small lot sizes, which they will not be able to manufacture economically. Since many manufacturers may not know what the best way to produce a part is, the MaaS providers are prepared to consult them on trade-offs of different manufacturing solutions and support them in their choices.

The suppliers in the marketplace are often small- or medium-sized companies. For them, this is an opportunity to acquire additional customers beyond their regular ones with limited efforts in sales and marketing.

However, MaaS will not be the “one size fits all” solution for making the supply chain “bullet proof”, as these platforms are suited to process spot demands and small lot sizes. Furthermore, customers should be aware that placing an order with MaaS means giving away part of production control and having no transparency over the production processes and technologies.

Despite these considerations, MaaS can significantly enhance the speed and security of the supply chain, with future opportunities to extend its range of services to more complex parts and lager lot sizes.

Eviden’s MaaS platform: Empowering stakeholders

Eviden has developed a platform that empowers customers and partners to create their own MaaS platform. This incorporates key features required for a seamless execution and control of the process between customers and suppliers:

- Processing and tracking incoming customer orders, protecting the transaction via Blockchain and providing order specific data

- Customer portal, the entry point for customers into the marketplace, getting insights into marketplace prices, terms and conditions, contracts, and product catalogues

- IT integration, including initiating backend system invoices to customers through the platform and integrating with payment systems

- Provision of quotations and price calculations for the parts and/or products request by the customer

If you would like to discuss successful MaaS stories and its application in your business, feel free to reach out to me for a detailed interaction.

References and sources

- [1] Source: CapitalIQ and Roland Berger: “On-demand manufacturing platforms are taking the sector by storm”, October 2023