Nuclear operators face increasing challenges in the power generation market. They must adapt to capitalize on emerging opportunities as nuclear becomes the baseload electricity source for a greener future. They need to build new nuclear power plants. These must be safer by design with construction accelerated and costs optimized. In parallel, they must maximize output from aging assets while minimizing operational costs and avoiding outages while containing maintenance and upkeep overheads.

Digital transformation in nuclear operations and maintenance is key to successfully addressing these challenges. It is also central to the imperative of retaining knowledge throughout the nuclear lifecycle through to decommissioning.

Adopting digital technology in nuclear can be challenging. In part, this is due to the many technical, safety, regulatory, commercial, and environmental constraints which characterize the industry. This is further complicated by the lack of industry-wide standards regarding digital adoption.

In nuclear, change management across people, process, and plant has, understandably, always been complex and costly. Furthermore, change management practices are not always directly applicable to digital technologies.

As nuclear turns to digital transformation, the industry must address people, processes, and plants, ensuring that safety remains at the heart of all implementations.

The legacy of regulation and operation

It is not surprising that nuclear operators have complex operational models. These are the result of eighty years of aggregated learnings used to refine process and procedure at a local and global level. While we need to respect the legacy of regulation and operation, it should not remain unchallenged. It is especially important to take a new look at the tools used to enforce processes and demonstrate compliance.

Data analytics is critical for nuclear in creating a consolidated view of people, process, and plant.It becomes essential to look beyond traditional operational silos and to apply the potential of analytics to core operational topics, including:

- IT/OT integration and cybersecurity

- Through-life management strategy

- Predictive maintenance/smart operations

- Connected plant and digital workplace

How, for example, can nuclear operators leverage data to deliver maximum value from their installed base of instrumentation and control systems? How can they adapt the Industrial Internet of Things (IIoT) to gain faster and cheaper monitoring of critical plant areas? Both of these are vital in the pursuit of optimized asset performance and, more specifically, in the effective implementation of a comprehensive approach to predictive maintenance.

Integrity and integration

Digital transformation in the nuclear industry hinges on the increased integration of Operational Technologies (OT) and Information Technology (IT). The associated process convergence must be prioritized, as nuclear operators adopt intelligent technologies while remaining focused on the need to maintain transparency, safety, and continuity.

As OT and IT become more widely integrated, so cybersecurity services and tools must be deployed both to detect anomalies and to provide insight into the landscape of threat, both internal and external.

The security case for every system and subsystem must be assessed in terms of confidentiality, integrity, and availability. This demands an intelligent OT cybersecurity infrastructure, which in turn allows for better detection and timely response. Pre-emptive action will become the norm and the foundation for the safe adoption of digital technology in day-to-day operations.

Nuclear operators will see significant cost savings and gains in operational efficiency if they are able to adopt proven in-use digital solutions. Reliance on bespoke technologies increases both costs and risks.

Effective strategies for managing obsolescence also become critical. Just as with every other aspect of the nuclear plant lifecycle, operators must have a clear view of ongoing financial commitments, and of futureproofing for safe and continued generation. Critical monitoring systems are also required for a period of post-operational life, supporting safe defueling and decommissioning.

This involves addressing midlife modification strategies; lifetime purchases based on field performance data; and policies and governance for the qualification of new devices. All this, in turn, is linked to knowledge retention and documentation.

Condition monitoring and mediation

In every nuclear plant, condition monitoring is central to the processes governing equipment reliability. Detecting plant anomalies uses multiples techniques. These include vibration monitoring, oil analysis, visual and sound analysis, and advanced current and voltage signal analysis for assets where sensors cannot be deployed or maintained.

Until now, many of these techniques have required the manual collection of data and samples with skilled personnel performing even the most basic of tasks. This is changing. Cost-effective edge and secure cloud computing combine with AI and the IoT to deliver real-time analysis of vast amounts of data. This allows for the generation of timely pre-emptive maintenance advice.

The early detection and remediation of issues before they materialize is central to both safety and operational efficiency in nuclear power. In many nuclear power plants, state-of-the-art condition monitoring methods are already in use. But as in many other industries, these activities are still resource-intensive and manual.

By utilizing edge computing, hybrid cloud and various analytics, it is now possible to leverage data and deliver predictive maintenance to stop minor issues becoming major and, at the same time, to gain actionable insight for continually improving operational efficiency. These initiatives must embrace security and must address the confidentiality of plant data.

Lifetime maintenance costs can be reduced by maintaining and acting on an active repository of critical data and performing advanced analytics to automate early detection of equipment malfunction. Outcomes also influence planning processes and operational decision-making.

The adoption of such technologies is critical in the nuclear environment. Not only do they support maintenance and statutory compliance activities, but also contribute to enhanced regulatory confidence in nuclear operators.

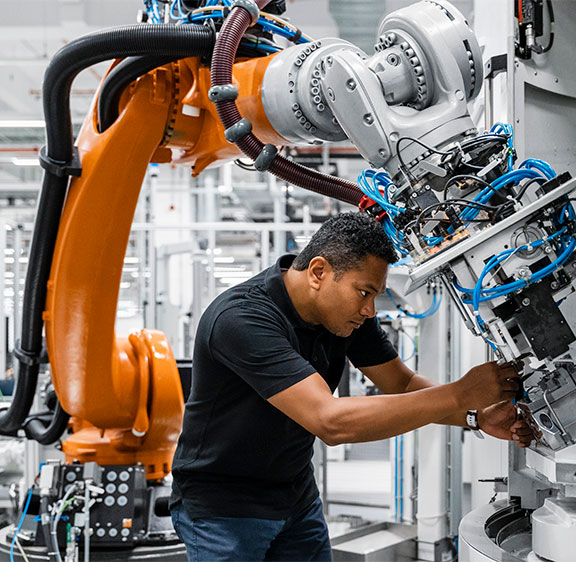

Nuclear operators must, of course, ensure personal safety from radiological and industrial hazards. This demands robust processes, which, today, are overwhelmingly enforced by manual controls. The individual use of digital tools such as smart wearables for health monitoring and geographical hazard information; computer vision for PPE checks and situation alerts; augmented/virtual reality for enhancing location awareness and automating processes are already an aid in improving human performance. Add more efficient communication links and advanced access control solutions, and nuclear operators can significantly improve day-to-day operational and safety performance.

Putting people first

Of the 3Ps, people are the most important. Nuclear operators need to employ qualified and experienced personnel and maintain the talent pool throughout its working life. It is ever more important to ensure better utilization of these highly-skilled resources and to attract fresh talent to the industry. Better utilization can be achieved by automating or simplifying repetitive or mundane tasks. This allows people to focus on more important critical operational and safety decision-making. Rapid information transfer enables experts to deliver timely and focused assistance to local operators and maintenance crews. It is also important to modernize the workplace and embrace technologies relevant to the current world: the latest generation of nuclear professionals are all digital natives. This transformation can be achieved through strategic investment and can be rapidly deployed through a well thought out digital transformation strategy focused on empowering the people at the centre of change.

Environment, decarbonization, optimization of supply chain and carbon footprint from day-to-day operations should also be considered to sustain the savings achieved by a transformation initiative. To maintain a sustainable business, nuclear operators must ensure safe and continued operation for the environment and community while delivering higher value from the energy they generate. Data-driven, connected nuclear operations will leverage proven technologies to meet this commitment, while at the same time becoming more competitive.